Modern construction is no longer just about cement, steel, and bricks. Today, construction chemicals play a critical role in improving strength, durability, workability, and long-term performance of buildings and infrastructure. From high-rise apartments and individual homes to bridges, factories, and commercial complexes, construction chemicals have become essential for achieving quality, safety, and cost efficiency.

This comprehensive guide explains construction chemicals in detail, with a clear focus on admixtures, sealants, and waterproofing systems—what they are, why they are used, how they work, and how to choose the right solutions for Indian construction conditions in 2026.

Table of Contents

What Are Construction Chemicals?

Construction chemicals are specially formulated products added during or after construction to enhance the properties of building materials. They help improve concrete strength, control setting time, prevent water ingress, seal joints and cracks, reduce maintenance, and extend the life of structures.

In India’s diverse climate—ranging from heavy monsoons to extreme heat—construction chemicals are no longer optional; they are a necessity for long-lasting and reliable buildings.

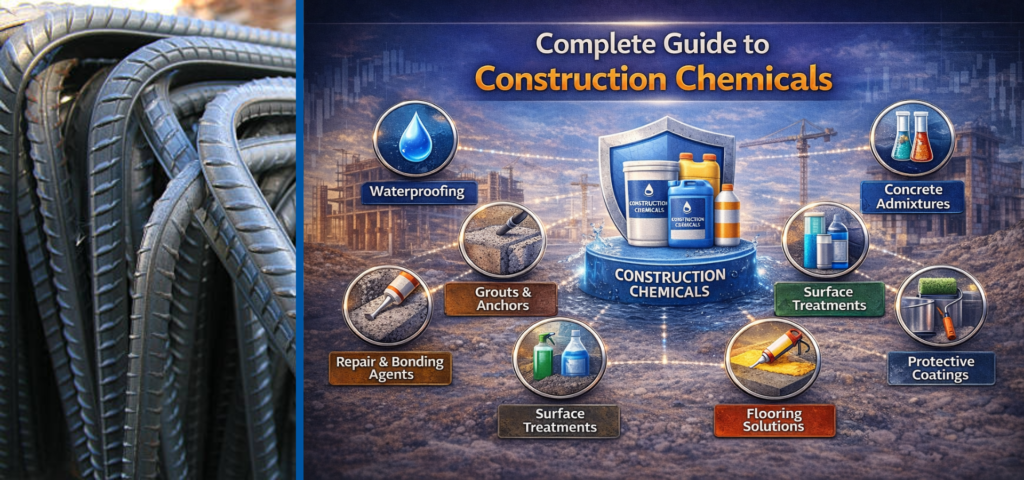

Major Categories of Construction Chemicals

Construction chemicals are broadly divided into three key categories:

- Concrete Admixtures

- Sealants and Joint Fillers

- Waterproofing Chemicals

Each category serves a unique purpose and must be selected carefully based on application, structure type, and environmental conditions.

1. Concrete Admixtures – Enhancing Strength & Performance

Concrete admixtures are chemicals added to concrete during mixing to modify its properties in fresh or hardened state.

Why Admixtures Are Used

- Improve workability without adding extra water

- Increase compressive strength

- Control setting and curing time

- Reduce permeability

- Improve durability and finish

Types of Concrete Admixtures

a) Plasticizers & Superplasticizers

These admixtures improve workability and flow of concrete while maintaining low water-cement ratio. They are essential for RCC work, slabs, columns, and beams.

b) Accelerators

Used when faster setting and early strength gain is required, especially in cold weather or time-bound projects.

c) Retarders

Slow down setting time, ideal for hot climates and large concrete pours where extended working time is needed.

d) Integral Waterproofing Admixtures

Mixed directly into concrete to reduce capillary pores and water absorption, improving internal waterproofing.

e) Air-Entraining Admixtures

Introduce microscopic air bubbles to improve freeze-thaw resistance and durability.

Benefits of Using Admixtures

- Stronger concrete with less cement

- Reduced cracks and shrinkage

- Better surface finish

- Improved long-term durability

2. Sealants – Protecting Joints, Cracks & Gaps

Sealants are flexible materials used to fill joints, gaps, and cracks to prevent water, air, dust, and chemical ingress.

Why Sealants Are Important

Buildings naturally expand and contract due to temperature changes, loads, and movement. Sealants accommodate this movement while maintaining a tight seal.

Types of Sealants

a) Polyurethane (PU) Sealants

Highly flexible and durable, suitable for expansion joints, façades, basements, and industrial floors.

b) Silicone Sealants

Excellent weather resistance and UV stability, ideal for glass, windows, and exterior joints.

c) Acrylic Sealants

Used mainly for internal cracks and paintable joints.

d) Epoxy Sealants

High strength and chemical resistance, used in industrial and heavy-duty applications.

Applications of Sealants

- Window and door frames

- Expansion joints

- Bathroom and kitchen joints

- Basements and podium slabs

- Industrial floors and warehouses

3. Waterproofing Chemicals – Defending Against Water Damage

Waterproofing chemicals prevent water ingress that causes dampness, leakage, corrosion, and structural deterioration.

Why Waterproofing is Essential

Water is the biggest enemy of buildings. Poor waterproofing leads to:

- Leakage and seepage

- Mold and damp patches

- Corrosion of steel reinforcement

- Paint peeling and plaster damage

- Reduced structural life

Types of Waterproofing Systems

a) Cementitious Waterproofing

Cement-based coatings used for bathrooms, water tanks, and basements. Easy to apply and compatible with concrete.

b) Liquid Applied Membranes (PU / Acrylic)

Form seamless elastic membranes for terraces, roofs, and podiums. Ideal for crack-bridging and UV resistance.

c) Bituminous Waterproofing

Used for foundations, basements, bridges, and industrial structures requiring heavy-duty protection.

d) Crystalline Waterproofing

React with concrete to form crystals that block water pathways permanently, ideal for underground structures.

Key Areas Requiring Waterproofing

- Terrace and roof

- Bathrooms and toilets

- Kitchen floors

- Basement and foundation

- External walls

- Water tanks

How Construction Chemicals Reduce Cost Long-Term

Although construction chemicals add to initial cost, they significantly reduce:

- Repair and maintenance expenses

- Structural damage risks

- Water-related failures

- Premature deterioration

In most cases, the return on investment is multiple times higher than the initial cost.

How to Choose the Right Construction Chemicals

Key factors to consider:

- Type of structure (residential, commercial, industrial)

- Exposure conditions (rain, heat, chemicals)

- Stage of construction (new or repair)

- Compatibility with cement and concrete

- Manufacturer reputation and certifications

Using the right product for the right application is critical.

Why Buy Construction Chemicals from Pahari Home Solutions

Choosing the right supplier is as important as choosing the right product.

Pahari Home Solutions Pvt. Ltd. offers

- Genuine, certified construction chemicals

- Solutions for residential, commercial & industrial projects

- Expert guidance on product selection and application

- Bulk supply and project-based orders

- Transparent pricing and reliable delivery

Contact for Premium Construction Chemicals

📞 Call / WhatsApp: +91 7584055356

🌐 Website: paharihomesolutions.in

Our team helps you select the most suitable admixtures, sealants, and waterproofing systems for long-term performance.

Frequently Asked Questions (FAQs)

1. What are construction chemicals used for in building projects?

Construction chemicals enhance strength, durability, workability, waterproofing, and overall performance of structures.

2. Are admixtures mandatory for modern construction?

While not legally mandatory, admixtures are highly recommended for quality, durability, and cost efficiency.

3. Can admixtures reduce cement consumption?

Yes. Superplasticizers allow lower water-cement ratios, improving strength with less cement.

4. Are sealants different from adhesives?

Yes. Sealants are flexible and accommodate movement, while adhesives are rigid bonding agents.

5. Which waterproofing method is best for terraces?

Liquid-applied membranes like PU or acrylic coatings are ideal for terraces.

6. Can waterproofing chemicals stop existing leakage?

Yes, repair-grade waterproofing systems can stop active seepage when applied correctly.

7. Is integral waterproofing enough for concrete?

Integral waterproofing improves resistance but should be combined with surface waterproofing for best results.

8. How long do waterproofing chemicals last?

High-quality systems can last 7–15 years or more with proper application.

9. Are construction chemicals safe for homes?

Yes, most modern products are safe when applied as per guidelines.

10. Can sealants be painted over?

Acrylic sealants are paintable; silicone sealants usually are not.

11. Do construction chemicals affect concrete strength?

When used correctly, they improve strength and durability.

12. Should waterproofing be done during construction or later?

During construction is best; post-construction waterproofing is more expensive.

13. Are cheap construction chemicals reliable?

Low-cost, unbranded chemicals often fail prematurely and increase repair costs.

14. How do I know which product suits my project?

Consult experts or reliable suppliers who understand application conditions.

15. Where can I buy genuine construction chemicals for my project?

From trusted suppliers like Pahari Home Solutions Pvt. Ltd., ensuring authenticity and technical support.

Conclusion

Construction chemicals have transformed the way modern buildings are designed, executed, and maintained. In today’s construction environment—where durability, safety, sustainability, and cost efficiency are equally important—admixtures, sealants, and waterproofing systems are no longer optional add-ons but essential components of quality construction. They directly influence the strength of concrete, the protection of joints and surfaces, and the building’s ability to withstand water, weather, and time.

Concrete admixtures enhance workability, strength, and durability while helping optimize cement usage and reduce cracking. Sealants protect the most vulnerable parts of a structure—joints, gaps, and interfaces—by accommodating movement and preventing water or air ingress. Waterproofing chemicals form the first and most critical line of defense against leakage, dampness, corrosion, and structural deterioration. Together, these construction chemicals ensure that a building not only meets design requirements but continues to perform reliably for decades.

In a country like India, where structures are exposed to heavy monsoons, humidity, temperature variations, and increasing urban density, the role of construction chemicals becomes even more critical. Skipping or underestimating their importance often results in recurring maintenance costs, premature failures, and safety risks. On the other hand, using the right construction chemicals at the right stage significantly improves lifespan, reduces long-term expenses, and enhances overall building value.

Equally important is sourcing these products from trusted and knowledgeable suppliers. The effectiveness of construction chemicals depends not just on the product itself, but also on correct selection, compatibility, and application guidance. Partnering with experienced suppliers ensures that builders, homeowners, and contractors receive genuine products, technical support, and solutions tailored to their specific project needs.

In conclusion, investing in high-quality construction chemicals is an investment in the future of your structure. Whether you are building a home, a commercial complex, or an industrial facility, thoughtful use of admixtures, sealants, and waterproofing systems will safeguard your project against time, weather, and wear. When quality materials are combined with expert guidance and proper execution, the result is a strong, durable, and maintenance-efficient building that stands the test of time.